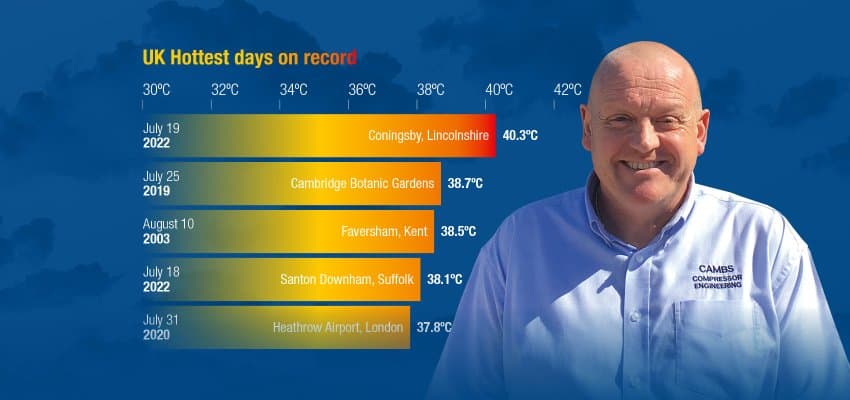

The east coast of the UK has recorded the five hottest days on record, so how does this hot weather impact on your compressor?

5 Things to watch out for and what to do about them

During hot summers, air compressor systems can face several challenges that can affect their performance and efficiency. Here are some of the biggest issues that can arise:

- Overheating: High temperatures can lead to increased heat generation within the compressor system. If the system's cooling mechanisms, such as fans or radiators, are unable to dissipate this excess heat effectively, the compressor can overheat. Overheating can cause damage to the components, reduce the compressor's lifespan and lead to unexpected shutdowns.

- Increased energy consumption: Hot weather forces the compressor to work harder to maintain the desired air pressure and temperature. This increased workload can result in higher energy consumption, leading to increased operational costs for the system.

- Reduced air quality: Warmer temperatures can increase the moisture content in the compressed air. Moisture, combined with other contaminants such as dust and oil, can lead to decreased air quality. This can impact the performance of pneumatic tools, machinery and processes that rely on clean and dry compressed air.

- Condensate issues: The higher humidity levels during hot summers can result in more condensate formation within the compressor system. If the condensate is not adequately drained or managed, it can accumulate in the system, leading to corrosion, water damage, and decreased system efficiency.

- Higher maintenance requirements: Hot weather can put additional strain on the compressor system, leading to increased wear and tear on components. This may require more frequent maintenance, including cleaning filters, checking lubrication levels, and inspecting belts and hoses.

To mitigate these issues, it is essential to implement proper maintenance practices and consider the following measures:

- Ensure proper ventilation and airflow around the compressor system to aid cooling.

- Regularly clean or replace air filters to prevent clogging and maintain efficient operation.

- Check and maintain appropriate lubrication levels for the compressor.

- Monitor and address condensate accumulation promptly through proper drainage and water separation systems.

- Consider installing additional cooling systems or insulation to regulate temperatures.

- Implement a preventive maintenance schedule to identify and address potential issues before they escalate.

By addressing these challenges, you can help ensure the smooth operation and longevity of your air compressor system, even during hot summer conditions.