Food and Beverage Grade Compressed Air Best Practice Guideline 102.

Food Safety Laws and Prevention

A critical component of the manufacturing, processing, packing, transporting and storing of food is ensuring that the compressed air is suitable for use in food and beverage applications. The focus of food safety and the laws governing it, is prevention rather than reaction. In other words, do not allow contaminated food products to ever reach the consumer’s table. These standards and codes do not define acceptable quality thresholds for compressed air used in food-related applications. In most cases, the standard simply reads that the air must be contaminant free, pose no risk, be safe for the consumer and be regularly monitored and tested.

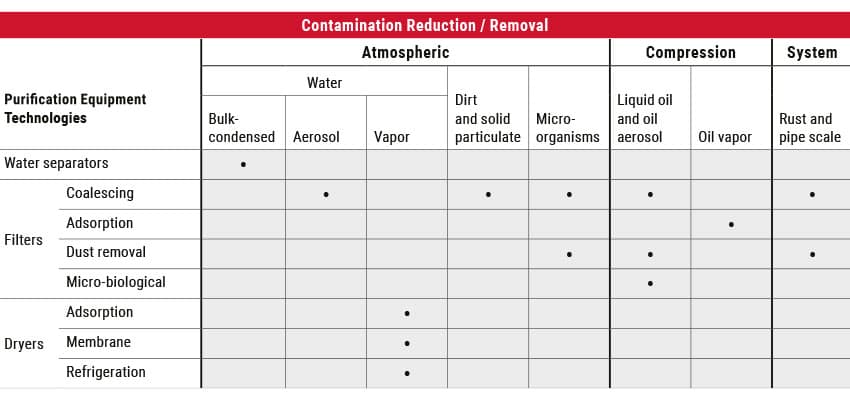

Ensuring compressed air is contaminant free and safe for use

Food safety laws are ambiguous with respect to acceptable levels of contaminants in compressed air for food applications. The ambiguity places the burden on the manufacturer, for determining and defining exactly what is considered suitable compressed air quality for their product. They must assume the risk of ensuring that the compressed air that they are delivering is contaminant free and safe for use.

Identify your risk, manage it, and monitor it.

The British Compressed Air Society has developed a useful document to offer advice to those seeking assistance; Food and Beverage Grade Compressed Air Best Practice Guideline 102. The purpose of this document is to make recommendations to the food and beverage industry on suitable air quality levels and advise the structure of a monitoring and verification program.

Risk prevention, which first starts with proper planning.

A good starting point is preparing a HACCP plan (Hazard Analysis and Critical Control Points) to identify the critical control points at which compressed air is in either direct or indirect contact with food. Establishing critical limits for these control points and establishing the proper processes for monitoring, testing, improving evaluating, and recording data on these control points.

In the case of compressed air, any point at which the air makes contact with the food, direct or indirect, represents a risk for contamination and therefore must be scrutinised under a HACCP program.

Monitoring and Verification, a Continuous Cycle.

By selecting an ISO 8573-1:2010 class 0 oil-free centrifugal compressor, you can rest assured that you are not adding oil into your compressed air process, thus leaving you free to direct your attention and efforts to reduce the risks posed by particles and humidity. Centrifugal technology also boasts other user benefits including reduced operating expense, lower maintenance costs and less downtime

The food safety laws, such as SQF and FSMA, do not specify required testing methodologies and frequency, but only that monitoring must be done on a regular basis to ensure that the air is contaminant-free.